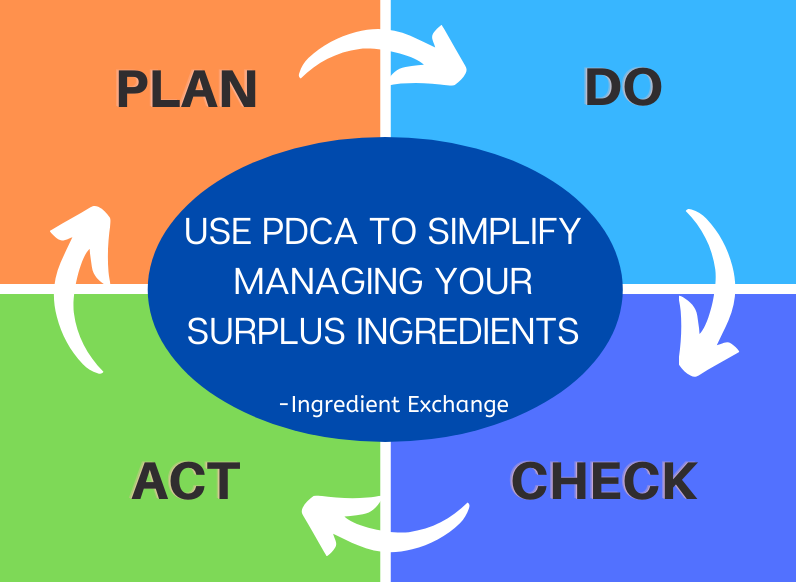

How to Use PDCA to Simplify Managing Your Surplus Ingredients

If you want to simplify managing your surplus food inventory—end-of-season and ongoing defect product—the PDCA cycle will make managing the excess ingredients much easier. What is PDCA? Plan-do-check-act (PDCA) is the repeatable four-step cycle for improving food manufacturing processes. It falls under the Continuous Improvement umbrella. By applying this simple PDCA model to managing your […]

How to Trade Your Bulk Off-Spec Dairy and Still Protect Your Brand

If 97% of bulk dairy production is in-specification, how do you manage the 3% that’s off-spec? One thing’s for sure, as long as production is up and running, manufacturing will continue to generate downgrade ingredients. Clearing out the accumulating inventory often falls to an in-house product manager or salesperson. An easy fix for offloading the […]

Do You Recognize These 4 Inventory Accumulation Problems?

As anyone in bulk-ingredient manufacturing knows, inventory accumulation is a nagging issue–one that can test the most squared-away plant manager. For the internal contact person assigned to manage off-spec inventory, the surplus product creates an ongoing challenge. They might rely on in-house tactics for clearing out the problem ingredients, including putting it on a bid […]